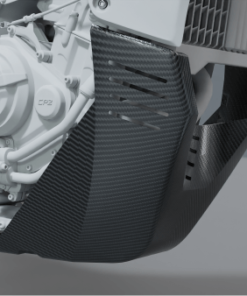

GP MUCCI THOR Skid Plate for Ténéré 700

€575.00

The most durable aluminum skid plate (bashplate) on the market. Thor from GP Mucci is the best protection you can give your Yamaha Ténéré 700 engine, fits each version and every model year, both EURO 4 and 5 Ténérés, except the World Raid.

This bashplate is powder coated to semi-glossy smooth black and completed with a silver mesh fixed behind the flaps / ventilation slots.

Available to ship immediately from stock!

1 in stock

*** Smooth black version, this version is better if you want to put stickers or decals on. Silver mesh (grill) fixed behind the flaps (ventilation slots). ***

Materials

This skid plate is constructed with the best aluminum for this application.

Working tens of tons of aluminum every year we can say that we know this material well, which comes in different types, each suitable for specific purposes. Some are very soft and could bend with bumps despite its thickness. Others cannot be bent as they would have cracks which over time would lead to breakage, others react to welding through “cooking” and become weak in the welded areas.

This type, however, is perfect for this application, which I also use for the tanks on rally bikes. Extremely hard, but which can be bent and welded without presenting the drawbacks described above, it is the same aluminum that is used in applications in the automotive field but with very different thicknesses.

Thicknesses

Our skid plate boasts a base of 5 mm, the one stressed by impacts, while the walls are 3 mm. The skid plates of the rally motorcycles that we have made over the years have never gone beyond 3 mm which I think is sufficient, but for safe measures we went a little further.

Welds

The skid plate is Tig welded externally by hand with meticulous control and careful attention to results. Internally it has reinforcements made with Tig / Mig. The welds are large and visible, we do not remove them because we believe that the functionality is more important. Also, visible welding on a rally or adventure bike, if done well, is a touch of quality.

Each welding is done by me, I do not delegate third parties.

Weight

Just under 4 kilos.

Fixings to the frame

To divide the load of the stresses to which this important accessory that must protect the engine can be subjected, we have increased the fixing points to the frame from 4 to 8, placing two in the upper part of the frame, near the radiator and two near the support of the leverage. We have chosen these points with care in order to improve the protection of the fabulous CP2, the engine that drives the Ténéré 700.

Ventilation

Modern engines run hot and the Yamaha CP2 needs to be ventilated in the oil filter area. This is because it mounts a water / air / oil exchanger which has the purpose of keeping the engine oil below certain temperatures. Basically there are two pipes of the cooling circuit that pass behind the oil filter in a finned flange that have this function.

We consider it a mistake to close the air passage in that area. We have therefore given a V shape to the front of the skid plate to force all the air that arrives in the area to enter the large air passage compartment in the skid plate.

We did not like this compartment and to hide it we have thought of everything, from a stainless steel mesh to other systems. In the end, for aesthetic and technical reasons, we opted for the current solution, a series of very sturdy horizontal bars that have such an inclination as to make our sump guard appear closed when viewed without bending over. But in reality the engine area is more ventilated than if the sump guard were not there.

Fixing brackets

To be mounted the skid plate uses 4 different fixing brackets which are made of steel and 3 mm thick stainless steel.

High tubular crash bars

Compatible high protection tubular bars:

- Touratech

- Hepco & Backer

- Motea

A kit is also available to make the skid plate compatible with the original YAMAHA bars.

Aftermarket exhausts

The CP2 engine of the Ténéré 700, like all modern engines, is very throttled and has a sudden performance improvement if the original manifolds are replaced.

We have tested the skid plate with the complete Akra, Sc Project, XRacing, Fresco, Mivv and Arrow collectors and our T7 skid plate is compatible with all of them.

From what we saw, Thor might be compatible with all the after market collectors / exhausts.

Central stand

The Yamaha original center stand assembly fits perfectly with our skid plate. To mount the central fixing of the skid plate it is necessary to partially disassemble the central stand, mount the sump guard support and refit the stand. We know that other manufacturers have created their own center stand but we have not tested its compatibility.

Related products

7 in stock

6 in stock

5 in stock

In stock ✓✓✓